Wire EDM is a manufacture process that produces sparks by means of electrical current to make the workpiece into the desired shape. Wire EDM is well suited for small, precise and complex shapes. It is commonly used in the manufacture of molds and dies, as these items must contain minimal residual stress. A dielectric fluid separates two electrodes and applies a voltage to produce a periodic, rapidly changing current discharge to process the material. One of the electrodes is called the tool electrode, or pole head, and the other electrode is called the work electrode, or simply the workpiece. During the EDM process, there is no actual contact between the tool electrode and the workpiece electrode.

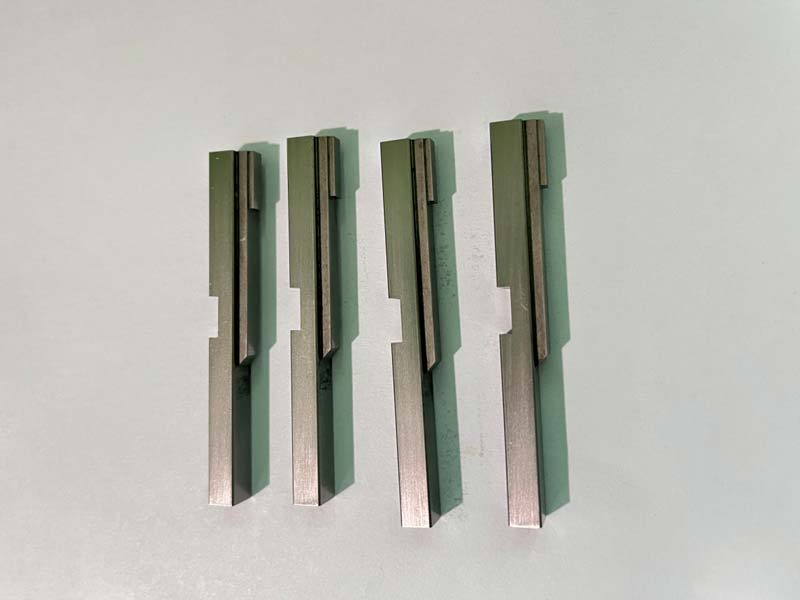

Multi-cutting technology is the fundamental means to improve the accuracy and surface quality of slow-walking processing. Generally, it is formed by one cutting, second cutting to improve the accuracy, and more than three cutting to improve the surface quality.

Advanced slow-walking processing machine tools use high-precision finishing circuit, which is an effective technology to improve the straightness of the processed artifacts, so that the accuracy of thick parts processing has been significantly improved; in order to carry out small rounded corners, narrow slits, narrow grooves and micro-fine parts of micro-fine processing, high-quality CNC low-speed wire EDM machine tools can use 0.02 ~ 0.03 mm electrode wire for cutting.

Adopt water temperature cooling device, so that the internal temperature of the machine tool is the same as the water temperature, reducing the thermal deformation of the machine tool; machining accuracy can be controlled within a number of microns, precision positioning can achieve 0.1μm equivalent control; adopt immersion processing, reducing the thermal deformation of the artifacts; motor servo, closed-loop electrode wire tension control. Adopt voltage modulation tool setting power supply to realize high precision tool setting, the precision of tool setting can reach 0.002 ㎜, no damage to artifacts, regardless of wet or dry.

Name | Description |

Model | VL400 |

Specs | X-Travel: 15.75″ (400 mm) |

Y-Travel: 11.81″ (300 mm) | |

Z-Travel: 8.66″ (220 mm) | |

Tolerance | ±0.002mm |

Wire Ø capabilities | 0.001-0.025mm |

Corner radius down to | 0.0015 |

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.