Most of the sheet metal welding methods use local heating, and the welded parts after welding will produce unavoidable stress and deformation in the structure, which will affect the structural load-bearing capacity, processing accuracy and dimensional stability, and also cause stress concentration at the junction of the weld and the welded parts, which will affect the brittle fracture of the structure.

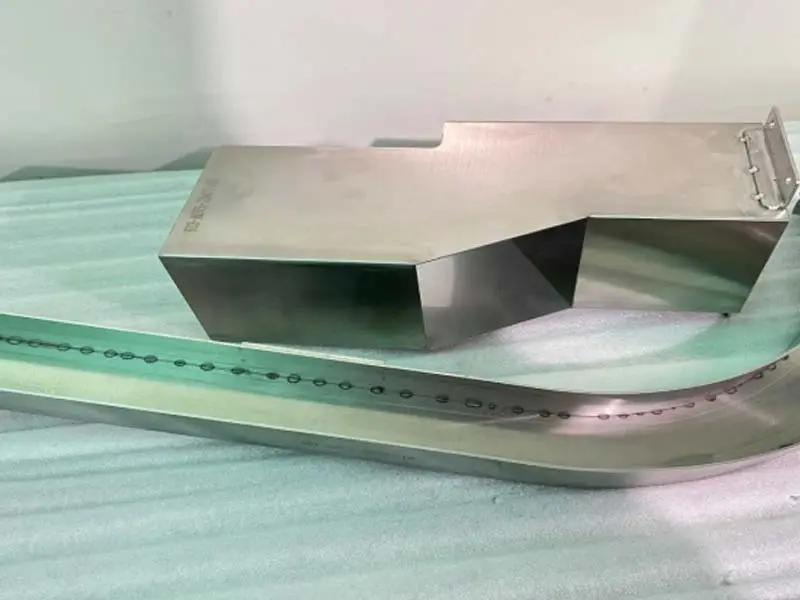

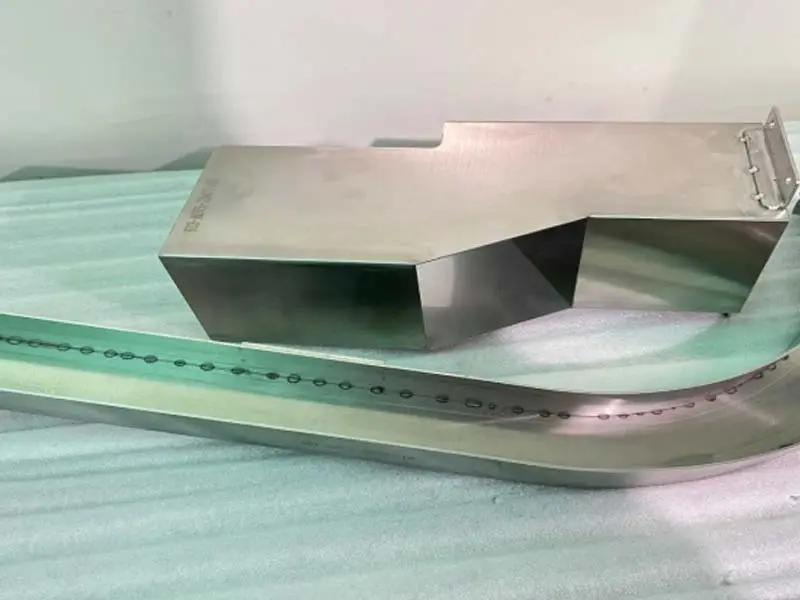

Splicing methods of sheet metal processing parts: The main work of sheet metal splicing uses welding, threaded coupling, riveting and bonding, commonly used splicing methods: welding, threaded coupling and riveting.

Welding - is the process of partial or overall heating or plastic deformation of the welded parts, or heating and plastic deformation at the same time, to achieve permanent connection, can be divided into: manual arc welding, gas shielded arc welding, laser welding, segment welding and contact welding, our main workers use gas shielded welding contact welding.

Threaded connection Threaded connection area easy to install, easy to disassemble, simple operation and other advantages, commonly used in the removable steel structure connection, it can be divided into screw coupling and bolt coupling.

Riveting Riveting is a method of using rivets to connect parts or assemblies of metal structures together, rivet types, we commonly used rivets are closed round head blind rivets, closed countersunk head blind rivets and open type round head blind rivets, open type countersunk head blind rivets.

Bonding The bonding agent will be required to connect the bonding sub ah together a connection method. However, for some special materials, laser cutting is also not possible.

Welding is a common way of joining work pieces in sheet metal processing. During the welding process of the work piece, care should be taken to prevent the deformation of the work piece. How can we prevent the deformation of sheet metal work pieces during the welding process?

Reduce the number of welds on the work piece while ensuring the basic shape of the work piece structure.

Balance the welding points and try to avoid concentrating them in one area, which will affect the aesthetics and cause deformation of the work piece.

Try to arrange the welding lines within the middle and symmetrically to ensure the aesthetics.

Consider the work piece when welding. Structure design, convenient to weld with tools, to ensure that the welding process of the work piece is not deformed.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.