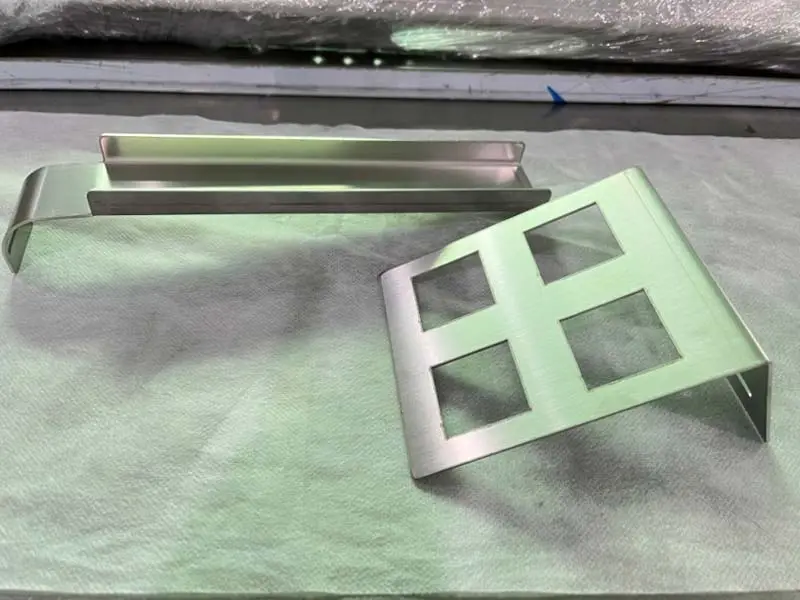

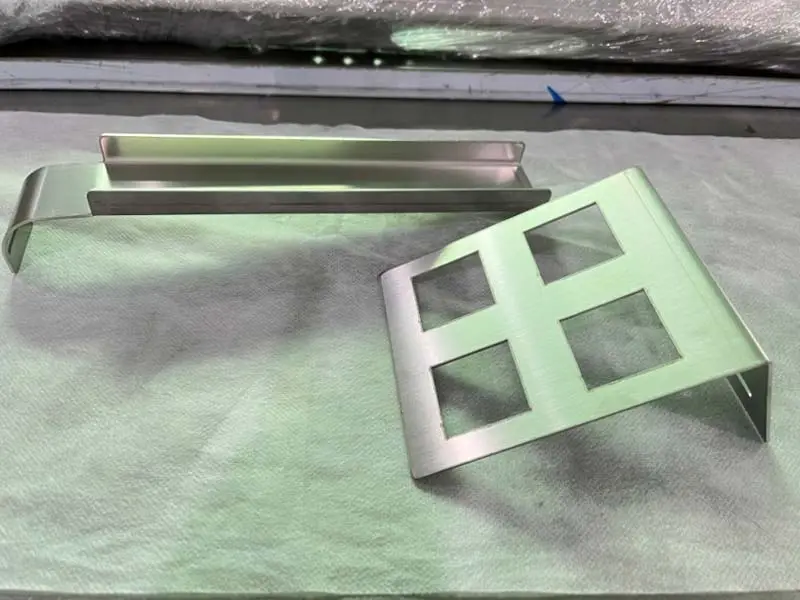

Sheet metal punching is a cut-off process in which material is being removed from a piece of sheet metal by applying a sufficiently large shear force.

CNC punching can be used to manufacture holes and cutouts of various shapes and sizes.

CNC sheet metal processing, its main characteristics are:

simple and convenient to use, for some of the more complex shape of the workpiece, or the thickness of the workpiece is relatively thin, it can be automatically completed processing. Moreover, its low input cost can help enterprises improve economic benefits.

The quality of the finished product is very good, because of its good flatness, high punching precision, so that the product can have a good consistency.

Because it can achieve mass production, and the production speed is fast, it can improve the production efficiency.

Sheet metal is metal that has been formed into a thin, ductile sheet while retaining the structural integrity and strength (unlike foil) of the metal surface. Aluminum, stainless steel, hot rolled steel and cold rolled steel are the four main types of sheet metal. Other common metals that can be sheet metal worked are carbon steel, bronze, copper, magnesium and brass. Carbon steel is easy to form and reasonably cost effective. The thickness of the sheet metal is a major factor. Sheet metal thickness and metal type of sheet metal may vary. The most typical sheet metal thickness is less than 1/4" thick.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.