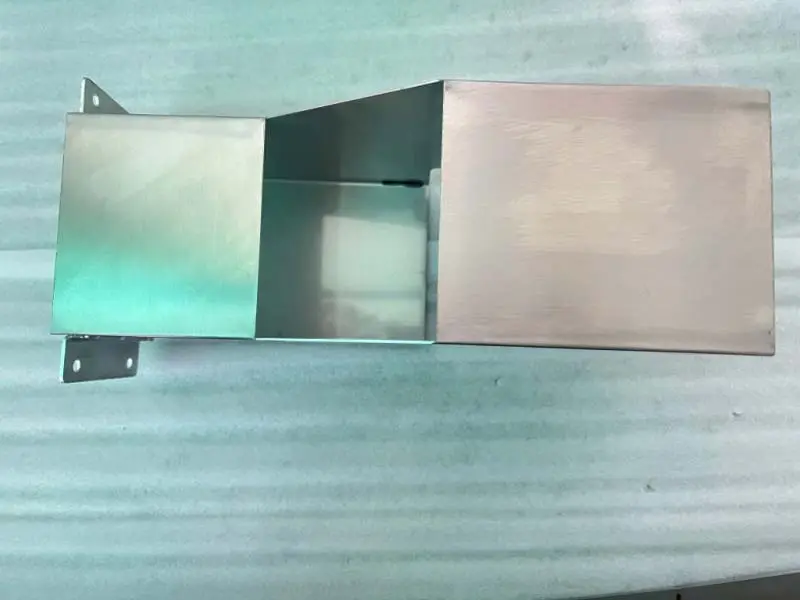

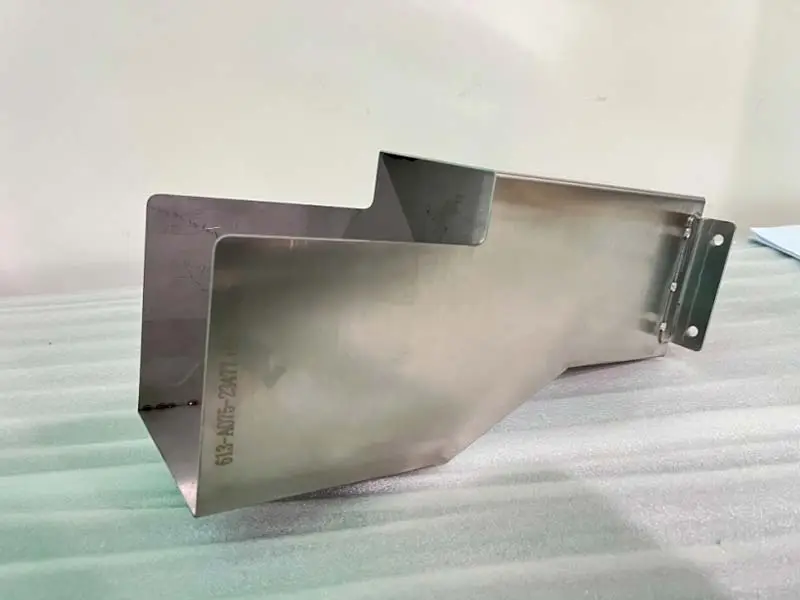

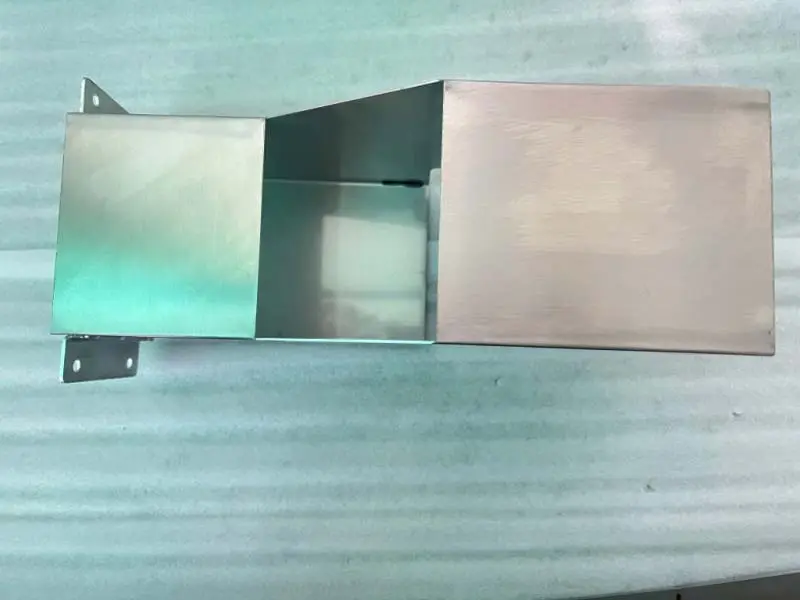

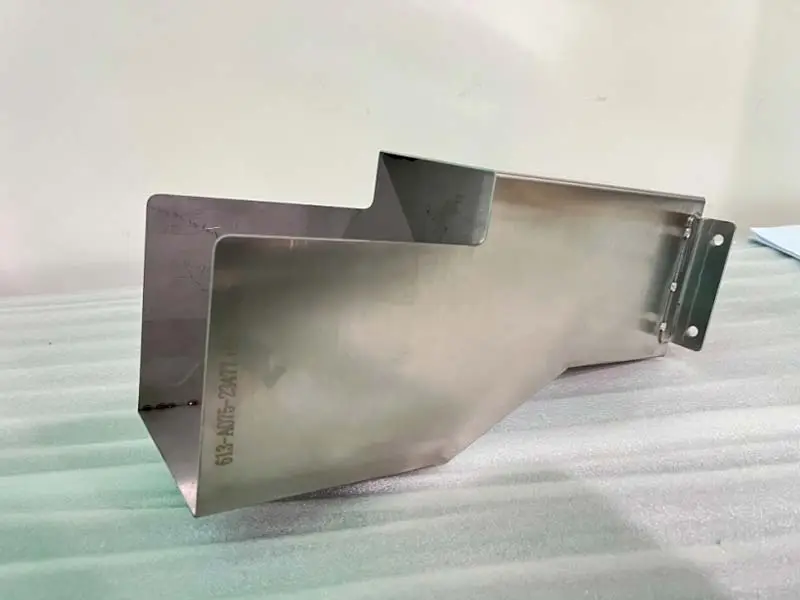

Sheet metal laser cutting is a process used to cut and shape sheet metal into various shapes and sizes. It is an industrial process that uses a powerful and precise laser beam to cut through a variety of metals, including steel, aluminum, brass, and other alloys. The laser beam is focused into a concentrated light beam and is used to heat up and melt the metal, allowing it to be cut into different shapes and sizes. The cutting process is both precise and efficient and produces high-quality results quickly. It is commonly used in the manufacturing industry for creating precision parts and components.

High precision parts

Durable materials

Customized design

Star-shaped punches

Modern surface treatment

Superior quality

Sizable production runs

Bump and dimple

Easy component nesting

Reduced scrap

Laser cutting is a sheet metal process that uses a laser beam to cut through materials like steel, aluminum, brass, copper and other metals. A computer-controlled laser beam is directed at the material, melting, burning, or vaporizing it into a desired shape. This process is highly accurate and repeatable and is used in a variety of industries, from automotive manufacturing to aerospace and medical. The process is also known for its speed and efficiency, as well as its ability to cut complex and intricate shapes.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.