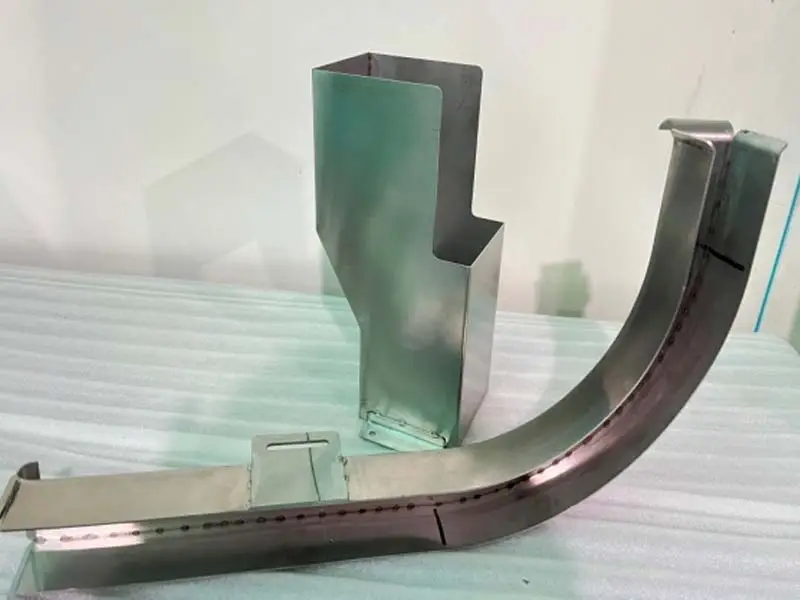

OEM sheet metal bending forms the wall of a sheet metal part into an oblique opening or cylinder shape. The CNC metal bending line is the reference point for calculating the unfolded length and creating the bending geometry. There are two CNC sheet bending classes with the time: angular and roll.

Carbon Steel. Carbon steel is one of the most flexible and strongest materials used for CNC sheet metal bending operations.

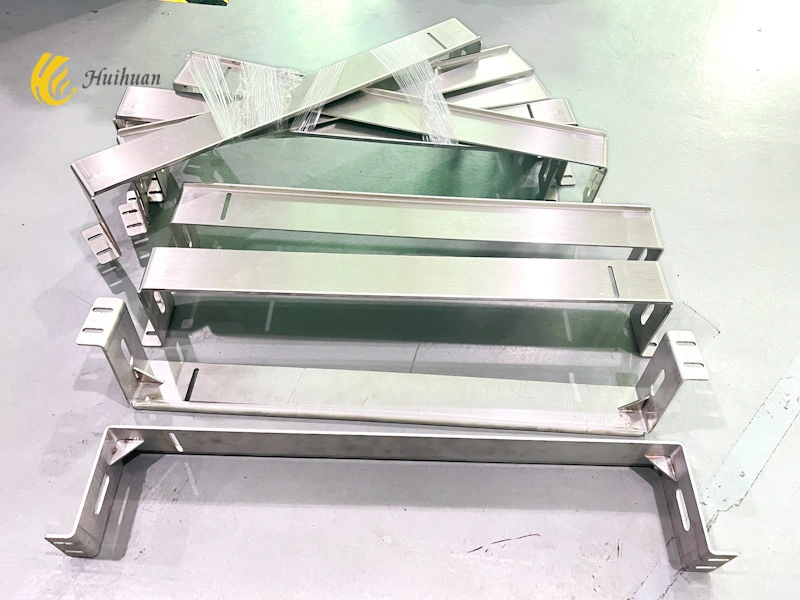

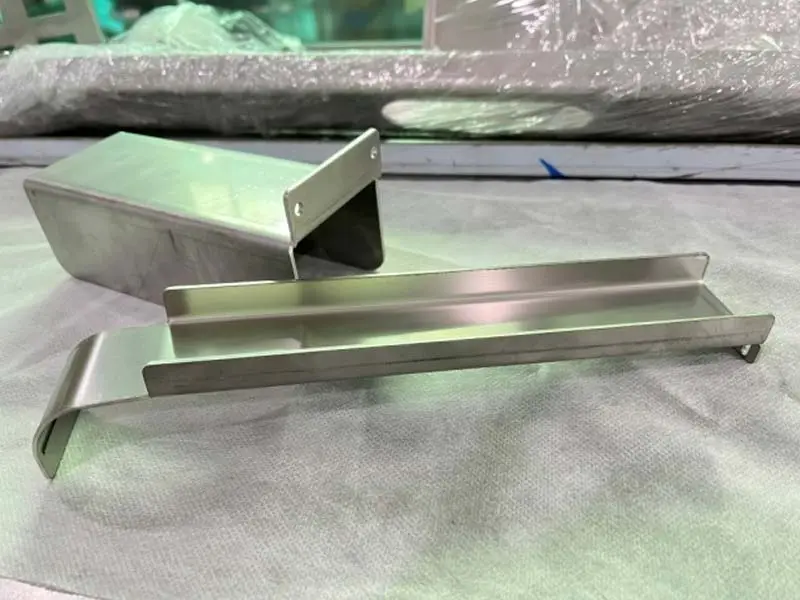

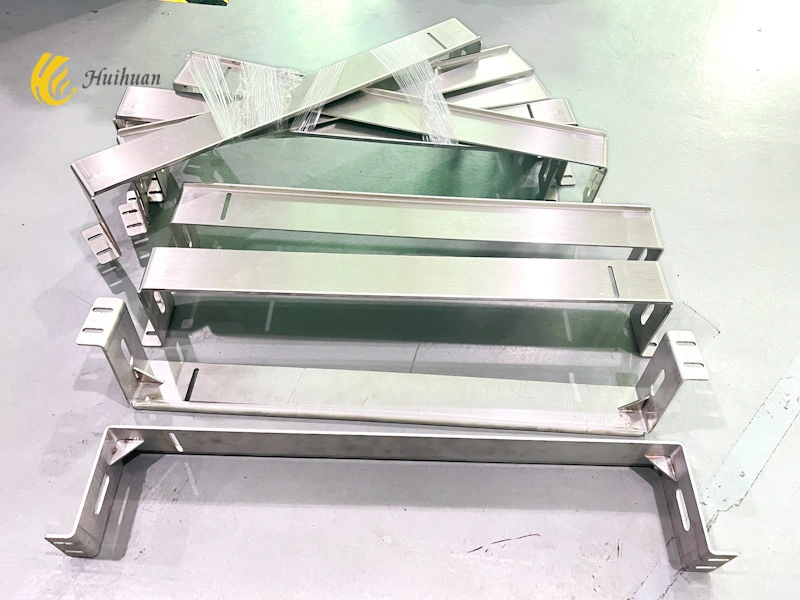

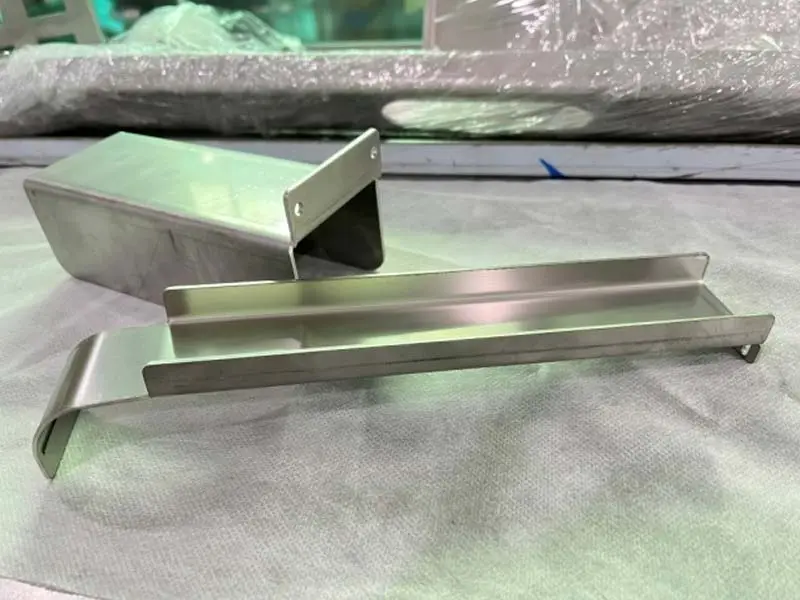

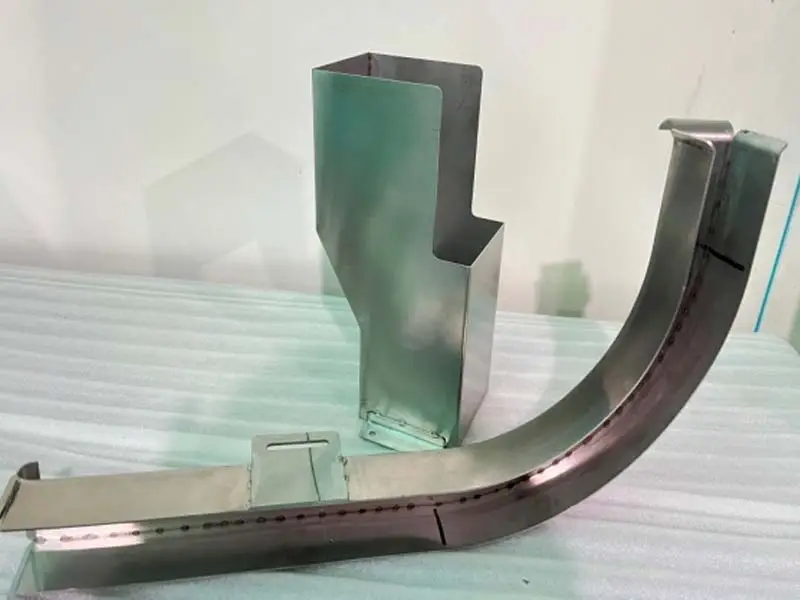

Stainless Steel. Stainless steel also requires the use of a high-powered custom sheet metal bending machine to form the product.

Aluminum. Aluminum is primarily used for lightweight applications. Special care must be taken when bending aluminum materials to avoid collapsing or cracking the corners of the material.

Copper. Cost is the strongest corrosion-resistant material and the cheapest. High precision custom metal bending is obtained from copper.

Titanium. Titanium is a corrosion resistant material and a high strength material - perfect for CNC sheet metal bending techniques. The material of choice for medical or sports equipment should be titanium

When sheet metal bending suppliers select materials used for various types of bending of sheet metal, these are some of the best options. Carbon steel is the most commonly used of the above materials.

Bending is one of the most common sheet metal manufacturing techniques. It is the plastic deformation of the workpiece on the shaft, resulting in a change in the geometry of the part. The CNC sheet metal bending allows for the production of a wide variety of part geometry using two processes: cutting and bending. The most common method of each process is CNC laser cutting and CNC metal bending machine bending. Bending may make a small change in the thickness of the sheet metal, but it does not basically change the thickness of the sheet metal.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.