OEM precision CNC Machining offers reduced production costs, increased speed, and fast and cost-effective prototyping. Key benefits of CNC precision machining services include producing complex CNC machining precision parts with high accuracy while keeping production costs low. Precision CNC machining service helps improve accuracy because it is a reliable and proven technology that greatly eliminates the possibility of human error.

In terms of cost reduction, precision CNC manufacturing not only reduces costs by reducing the need for skilled operators, but it also reduces the total amount of material waste.

Another advantage of custom CNC precision machining is the improved workflow from CNC prototyping to full production. At the prototyping level, CNC machines allow developers to quickly build functional designs that can be used for testing.

Each step significantly reduces turnaround time, enabling companies to significantly reduce the cost of missed opportunities.

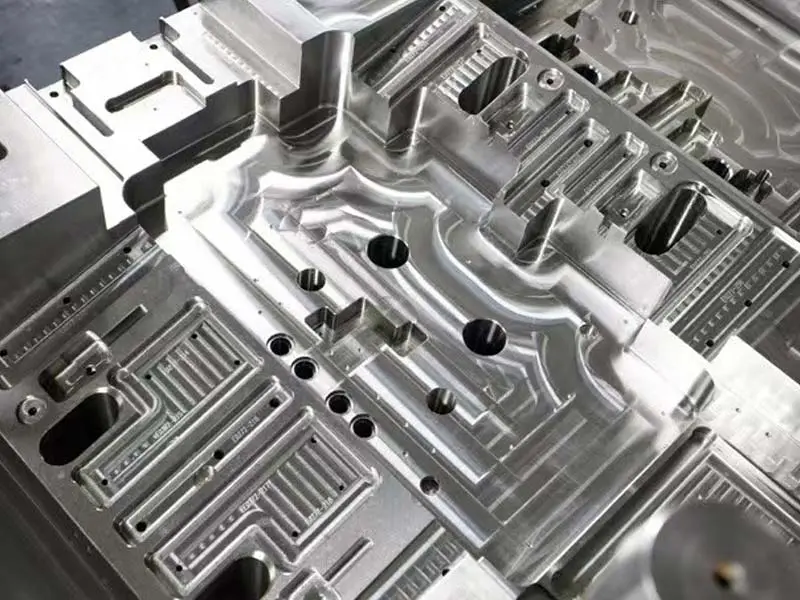

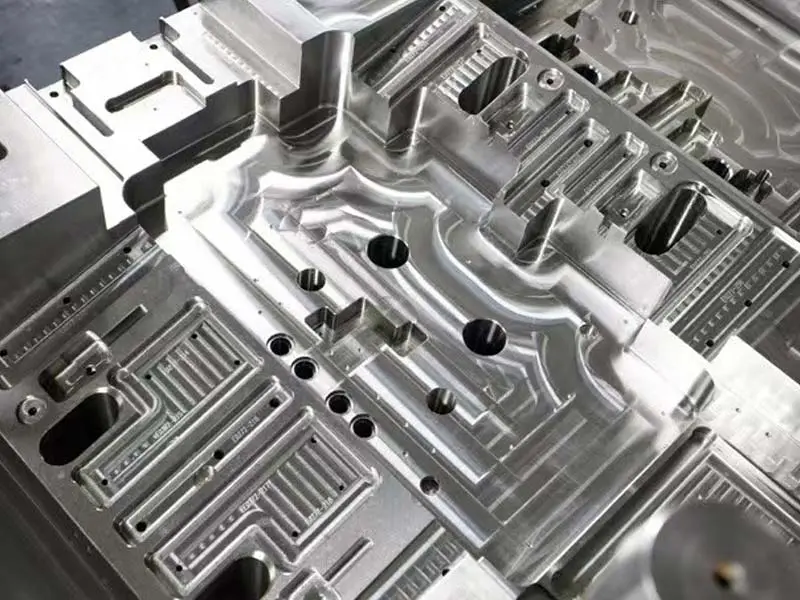

OEM precision CNC machining involves molding raw materials into finished products by cutting excess parts specified in computer-aided design (CAD) or computer-aided manufacturing (CAM) blueprints. Engineers working in the CNC precision machining company use this process on a variety of precision CNC manufacturing processes and different materials.

The standard tolerance for custom precision CNC machines is 0.005". At RapidDirect, our 5-axis precision CNC machines can achieve tolerances as high as 0.002". Our standards for OEM precision CNC machining are DIN-2768-1-fine for metal and DIN-2768-1-medium for plastic.

Single-sided tolerance measurement | In tolerance measurements, deviations are only allowed on one side of the nominal value. |

Ultimate Tolerance | This is when the tolerance value of the precision CNC machining lies within a range. For example, if the nominal value of the shaft is 10 mm and the tolerance is 10 - 10.5 mm, this would indicate a limit tolerance. |

Bilateral tolerances | This type of tolerancing allows for deviations on both sides of the nominal value. It is generally expressed as a +/- value |

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.