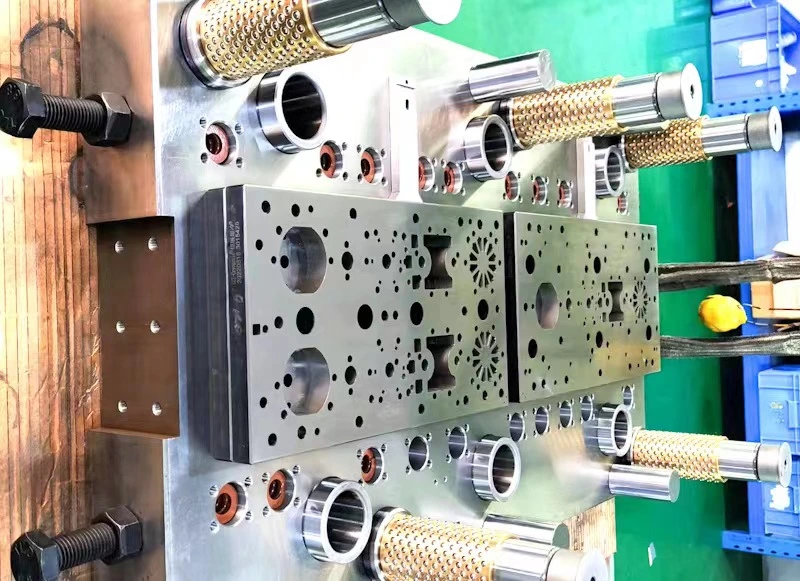

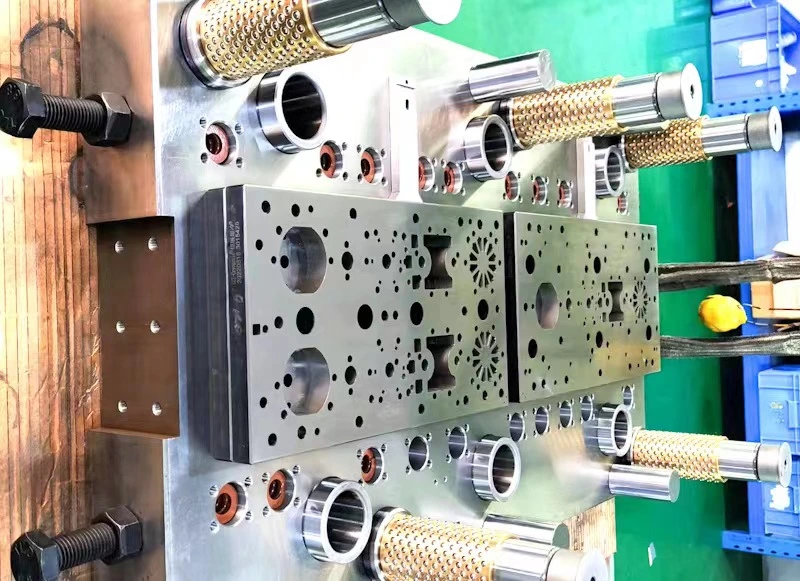

Hardware mold is a metal mold used to create customized pieces of hardware. It is typically used to create metal parts such as screws, nuts, bolts, rivets, and other metal components. The mold is made of a hardened steel or aluminum alloy, which is then machined to shape. The pieces of hardware are then placed into the mold, and heated until the metal is soft and malleable. The metal is then shaped into the desired shape using a hydraulic press or other tooling. The finished pieces are then ready for use.

Punching die A die that separates materials along a closed or open contour line. Such as drop die, punching die, cutting die, notching die, cutting edge die, cutting die, etc.

Bending die The die that makes the slab blank or other blanks along the straight line (bending line) to produce bending deformation, so as to obtain a certain angle and shape of the workpiece.

Deep drawing die is the die that makes the sheet blank into open hollow parts, or makes the hollow parts change shape and size further.

Forming die is a die that directly replicates the shape of the blank or semi-finished workpiece according to the shape of the convex and concave die, while the material itself only produces local plastic deformation. Such as expansion die, indentation die, flaring die, undulation forming die, flanging die, shaping die, etc.

Riveting die is to use external force to make the participating parts connected or lapped together in a certain order and manner, thus forming a whole.

Mold designer according to the product (parts) use requirements, design mold structure and make drawings. Skilled workers then make the molds according to the drawings using various mechanical processes. Then the mold assembly and debugging, until the production of qualified products.

Because the mold shape can be very complex, the product may have high requirements for structural strength, stiffness, surface hardness, surface roughness and machining accuracy, so the mold making has high requirements for technical level. Mold quality directly affects product quality, the timeliness of mold supply will affect the cost of new product development. Therefore, mold production quality and productivity are important factors of precision machinery manufacturing.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.