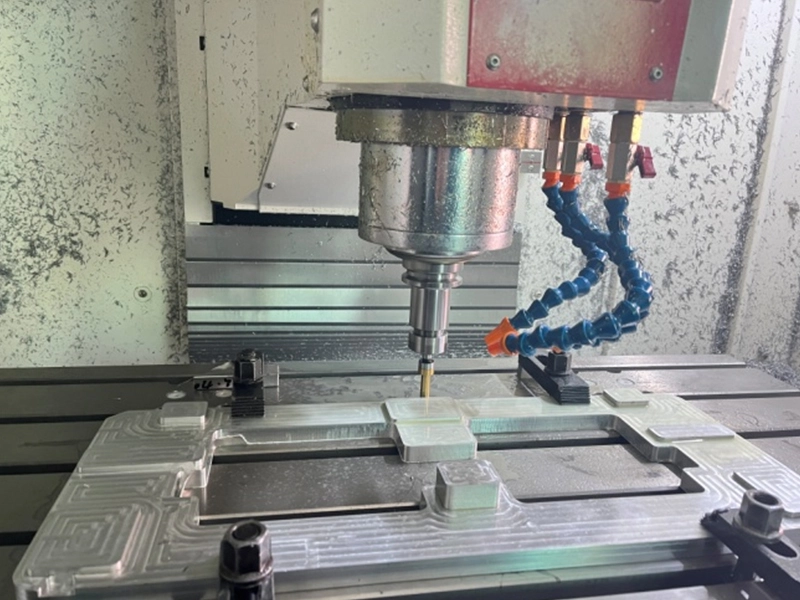

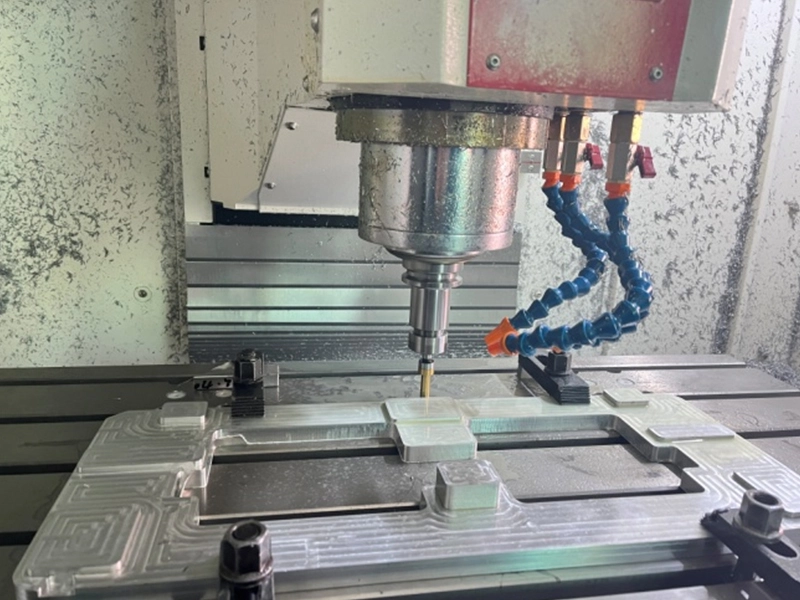

CNC Milling is the ideal method for rapid prototyping and for batch manufacturing of plastics and metals. We provide you with fast CNC machining services and manufacturing services. It is the process of using a revolving tool to remove material by pushing the tool into the workpiece. This may be accomplished by changes in direction, cutter speed and pressure on one or several axes. Milling covers a wide variety of operations and machines, ranging from small individual parts to large, heavily grouped milling operations. It is one of the most common processes for machining custom parts to exact tolerances. Milling can be performed using a wide variety of machines.

CNC milling is a machining process that uses a cutting tool mounted on a rotating spindle to selectively remove material from the original substrate. The workpiece is firmly mounted on the table and the table moves or rotates in different planes, so the tool can work at multiple angles. Complex CNC milling machines can have five or more independent axes of motion to create more complex shapes or to avoid moving the workpiece to one machine. The milling process can be divided into vertical and horizontal milling, circumferential and end milling and down and reverse milling depending on the milling machine, the milling tool and the form of motion.

CNC milling is a machining process that uses Computer Numerical Control (CNC) to create precision parts and components with tight tolerances. This process involves the use of a milling machine equipped with cutting tools to remove material from a workpiece. CNC milling is capable of producing complex shapes, intricate details, and smooth finishes, making it ideal for a wide range of applications, including automotive, aerospace, and medical components.

Max dimensions | 1600mm x 1200 mm x 900 mm |

Tolerance | Linear dimension: +/-0.025 mm Hole diameters (not reamed): +/- 0.025 mm Shaft diameters: +/- 0.025 mm |

Min. feature size | The smallest feature size we make is 0.5 mm, it depends on the product geometry and the material used. |

Burrs and chamfers | Default deburring and chamfering as per drawing processing requirements |

Surface Finish | The standard surface finish is 32 Ra or better. |

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.